Maintaining the lifespan of the compressor and system with the APR Control

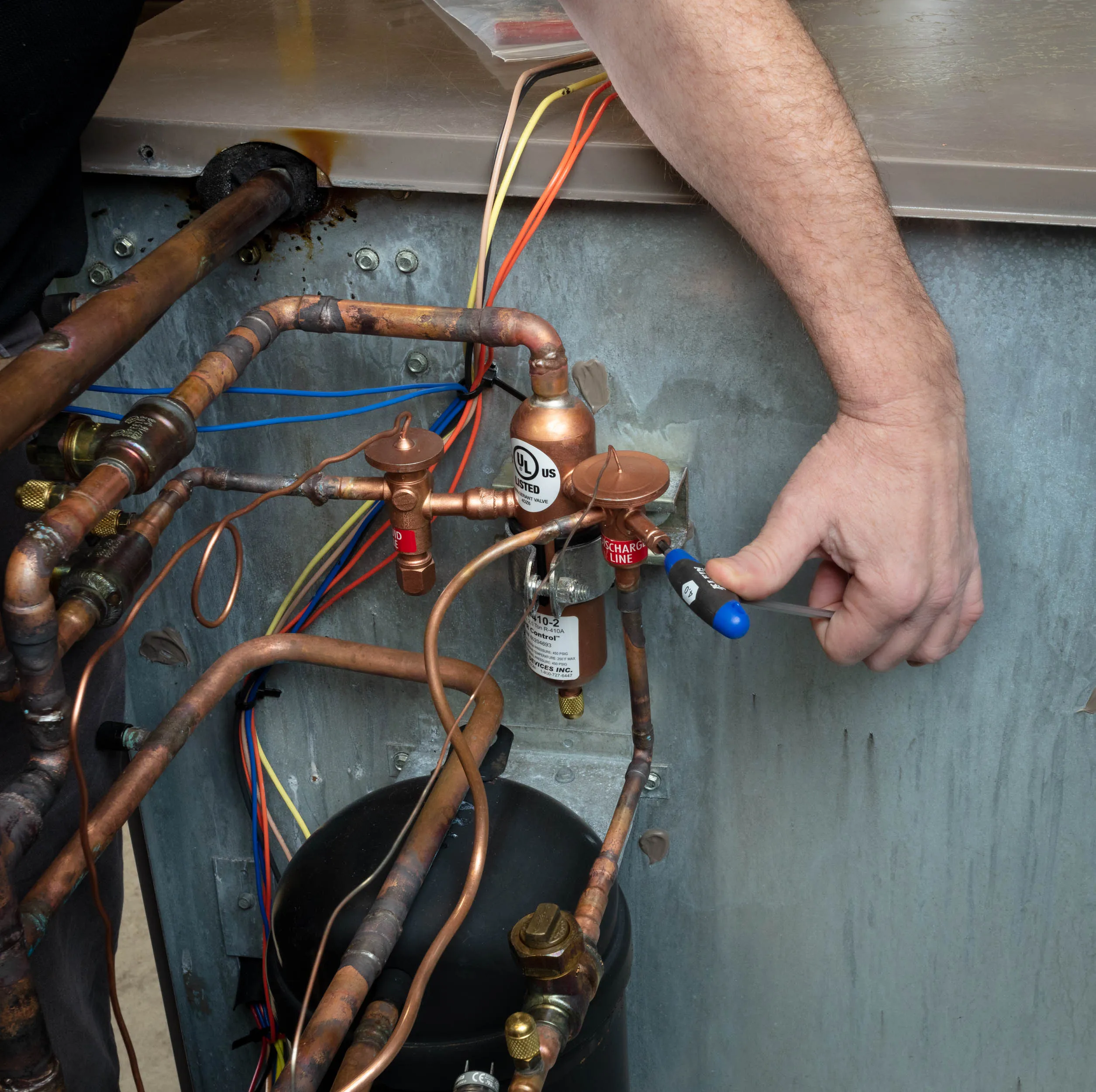

A system that has the ability to modulate capacity also can provide better reliability and fewer operating problems. These often are related to stresses placed upon the system’s compressor. Short cycling, low airflow, and other system problems can easily be corrected with the APR Control – reducing call backs and warranty issues, even on new systems.

Download & Share: How to Extend the Life of Your R-410A Equipment!

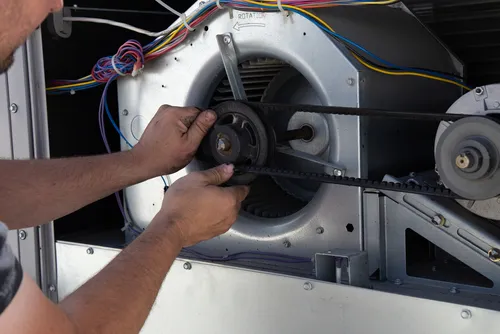

Excessive compressor cycling

This results from too much system capacity, oversized for the load, and leads to stress on the compressor from repeated starts and stops over a short time frame. If a compressor’s expected life span in normal usage is 10 years, then doubling the number of starts from an oversized system will most likely mean a significant reduction in the unit’s lifespan. Condenser and evaporator fan motors, compressors, and possibly coils are at risk when systems are cycling excessively.

Evaporator coil frosting

This is a costly consequence that results from one of several factors including: low air flow (from poor duct design or installation), dirty filters (from improper or inadequate maintenance), insufficient heat load, or improper use of system controls (thermostats). The ability of the APR Control to modulate a system’s capacity eliminates this problem by setting the device in a way that never allows the coil temperature to fall below freezing.

The APR Control enables the system to compensate for these problems, allowing its operation without the major expense of changing equipment or installing ductwork. Avoiding this problem also mitigates the risk of coincidental problems such as water damage resulting from the thawing of frozen coils.

Liquid slugging

This can result from inadequate heat transfer from the air such that the refrigerant does not boil off as intended. Should the liquid return to the compressor without having boiled into a gas, the liquid (slug) could permanently damage the compressor.

Reducing down time from repeated service calls, call backs, and warranty issues

Reducing the risks to the refrigerant circuit, demonstrated above, will reduce and eliminate the stresses on the system and compressor leading to improved system reliability and availability. The APR Control can quickly pay for itself by reducing the costs associated with repeatedly attempting to correct problems and reducing the cost associated with corrections that might be useful but not necessary.

Reducing labor-intensive and costly warranty and service calls associated with a “Full Service Agreement” make the APR Control a very cost-effective solution for problem systems.

Case Studies