Loved by contractors, service technicians, and customers

-

Reduces call-backs and saves warranty reserve funds

-

Technician-friendly: simplify installation, start-up, and service

-

Avoid costly system replacement and downtime

-

Reduces call-backs and saves warranty reserve funds

-

Technician-friendly: simplify installation, start-up, and service

-

Avoid costly system replacement and downtime

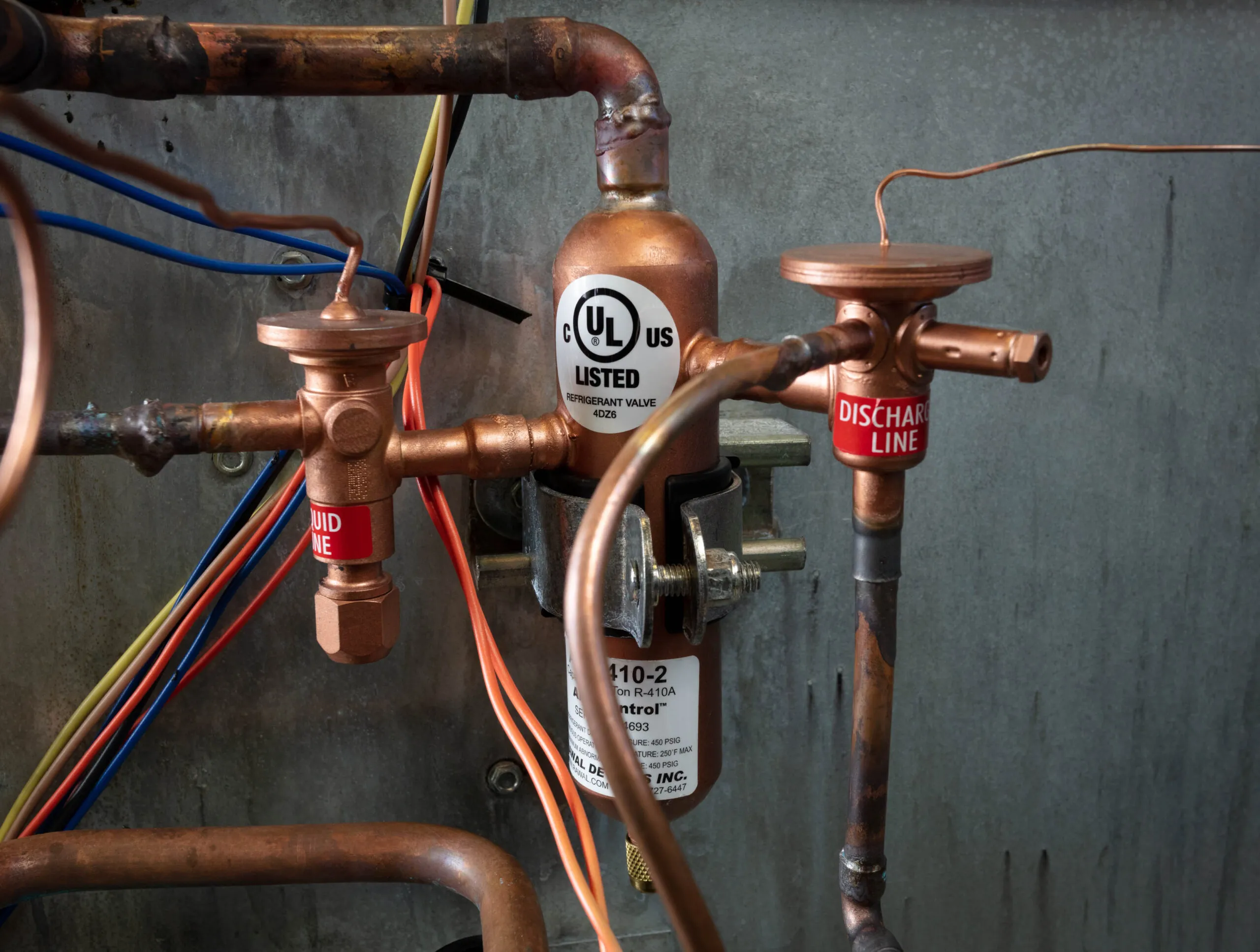

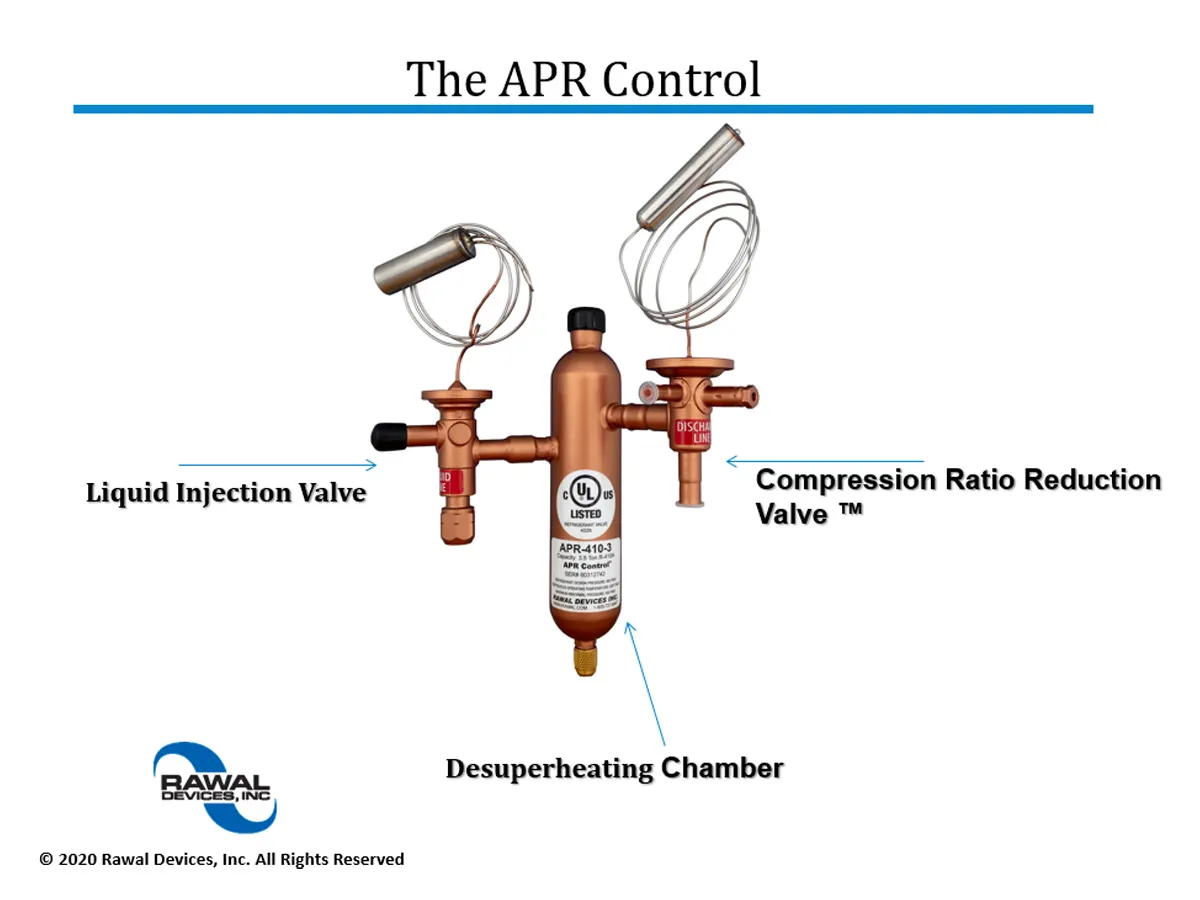

Rawal APR Control:

An easier solution for all of your DX HVAC customers

Keep your service customers comfortable and happy

As a contractor or service technician, your goal is to build lasting relationships with your facilities customers. A poorly functioning, or disabled HVAC system decreases productivity, and your customer’s bottom line! Keep your customer (and their wallet!) happy by delivering an optimized system, within budget, with the APR Control!

- Repair or modify existing in-place equipment

- Reduce call-backs stemming from customer complaints

- Maintain lasting relationships with your service contract customers

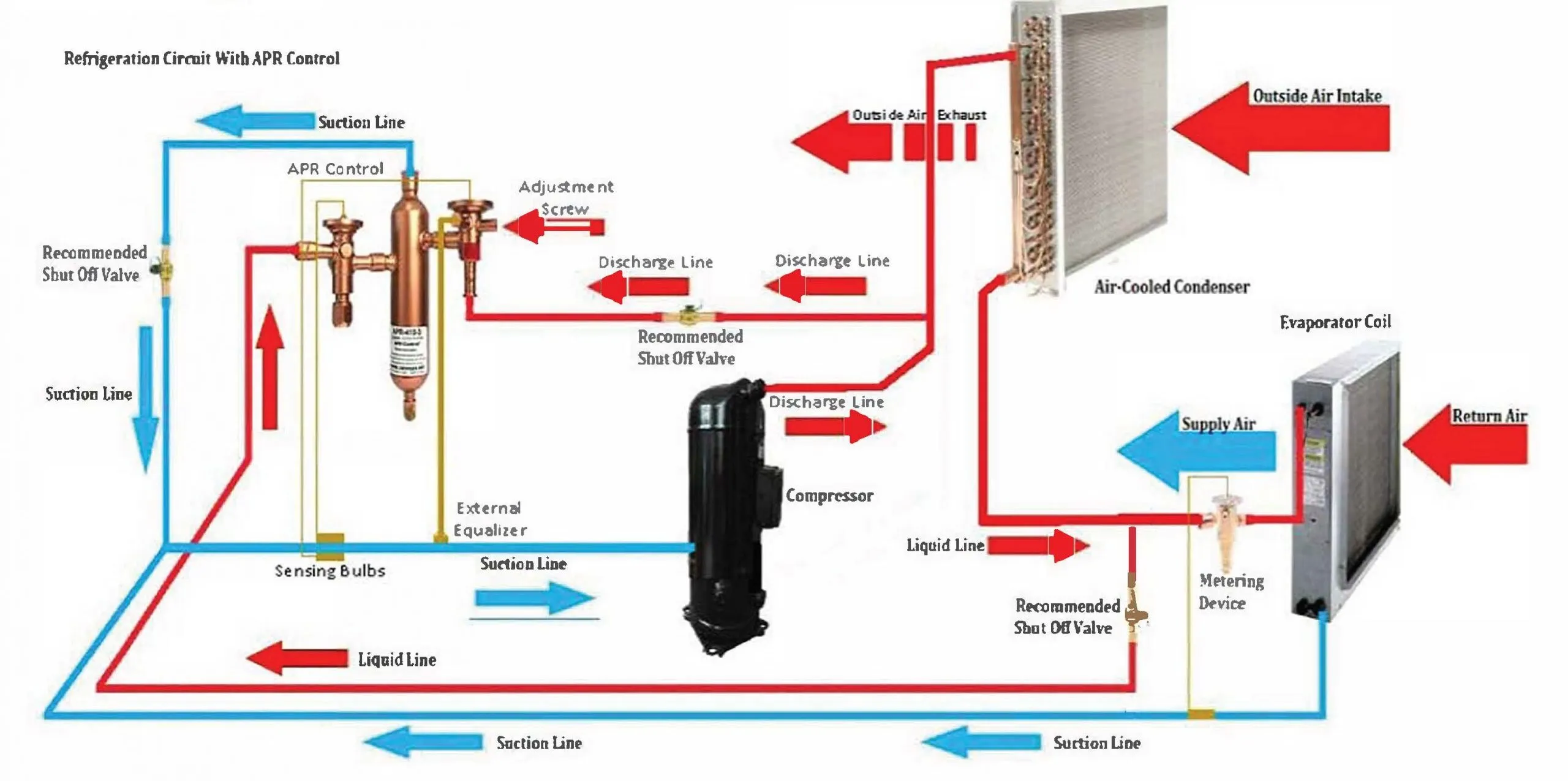

Modify any DX system to operate as a modulating variable capacity system

Rawal APR Control is a variable capacity enhancement for new and existing DX (direct expansion) systems in a wide range of commercial and industrial facilities and applications that helps provide:

- Tight temperature control

- Better humidity control

- Improved high-percentage outside air

- System protection (fewer call-backs)

Common HVAC Challenges

See below to learn more about how the APR Control is a solution for common customer complaints and the underlying causes.

| Problem | Diagnosis | Solution |

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

For Contractors

Flexible Solutions

Help HVAC systems respond to dynamic load criteria

- Cost-effective

-

Rehabilitate instead of replacing units in existing spaces

- As much as 80% turndown on standard DX systems

-

The APR Control delivers true load-matching performance

- Continuous dehumidification

-

Extend compressor run-time and maintain evaporator coil in dehumidifying mode

- Draws lower power during modulation

-

APR Control unloads the compressor, reducing kW/hr

Shorter lead times

Deliver the right solution to your customer in less time

-

Standard HVAC equipment can be customized for special applications, especially with budget or lead time constraints

-

Eliminate the need for expensive customized equipment with long lead times

- Applicable to a wide variety of systems and solutions:

-

Spaces with frequent load fluctuation such as schools, offices, and manufacturing facilities

-

VAV, VVT, make up air, and high percentage outside air applications

Value engineering option

Provide the right solution for your customer’s budget

-

Reduce up-front equipment costs

-

Provide variable capacity without use of expensive, complex technology

System protection for variable airflow volume (VAV) applications

APR Control allows for significant airflow reduction across the evaporator coil to provide optimal system performance

-

Systems with VFD on evaporator fan motors require APR Control to prevent compressor damage and provide consistent discharge air temperature

-

APR Control protects refrigeration circuit from coil freezing during low airflow operation

For Service Technicians

Complete problem jobs in less time

Service Technicians love the APR Control

-

Save warranty reserve funds and reduce call-backs

-

Technician friendly– simplify installation, start-up, and service

For Service Technicians

Correct over-sized equipment by adding APR

-

Improve designs to enhance performance

-

Eliminate inconvenient and excessive call-backs

-

Increase service pull-through work and sales

-

Provide a comfortable environment for your customer

-

Protect systems from missed preventive maintenance/service

-

Strengthen relationships with service / maintenance customers

Contractors & Service Technician Resources

-

How to Sell The APR Control