The Challenge

The Harvard laser labs were cooled by 2-ton R22 rooftop units (RTUs) equipped with a heat pipe wrap-around coil for reheat, along with a separate air handling unit (AHU) managing return air. These units handled 100% outside air and provided 300 to 700 CFM of airflow. However, as coils became wet, labs experienced poor temperature and humidity stability — making it difficult to maintain the precision environmental conditions these labs require, while also reducing overall equipment life. This created problems for lab users and leading to unnecessary operational headaches.

For Facilities and Building Managers, especially at schools and universities, challenges like these raise a critical question: Should you invest in expensive new variable speed HVAC systems, or is there a more cost-effective and reliable solution to enhance temperature and humidity control with your current equipment?

The Solution

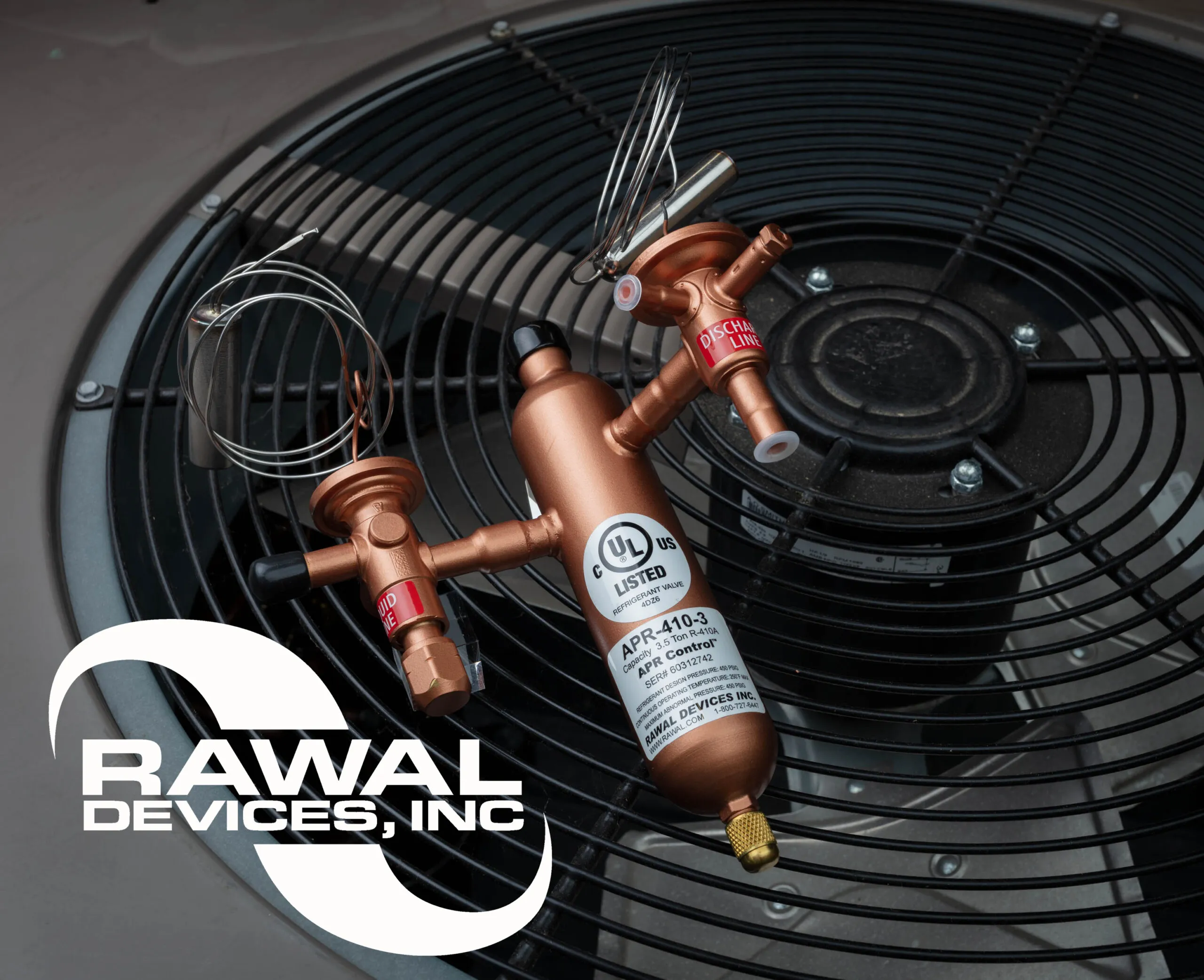

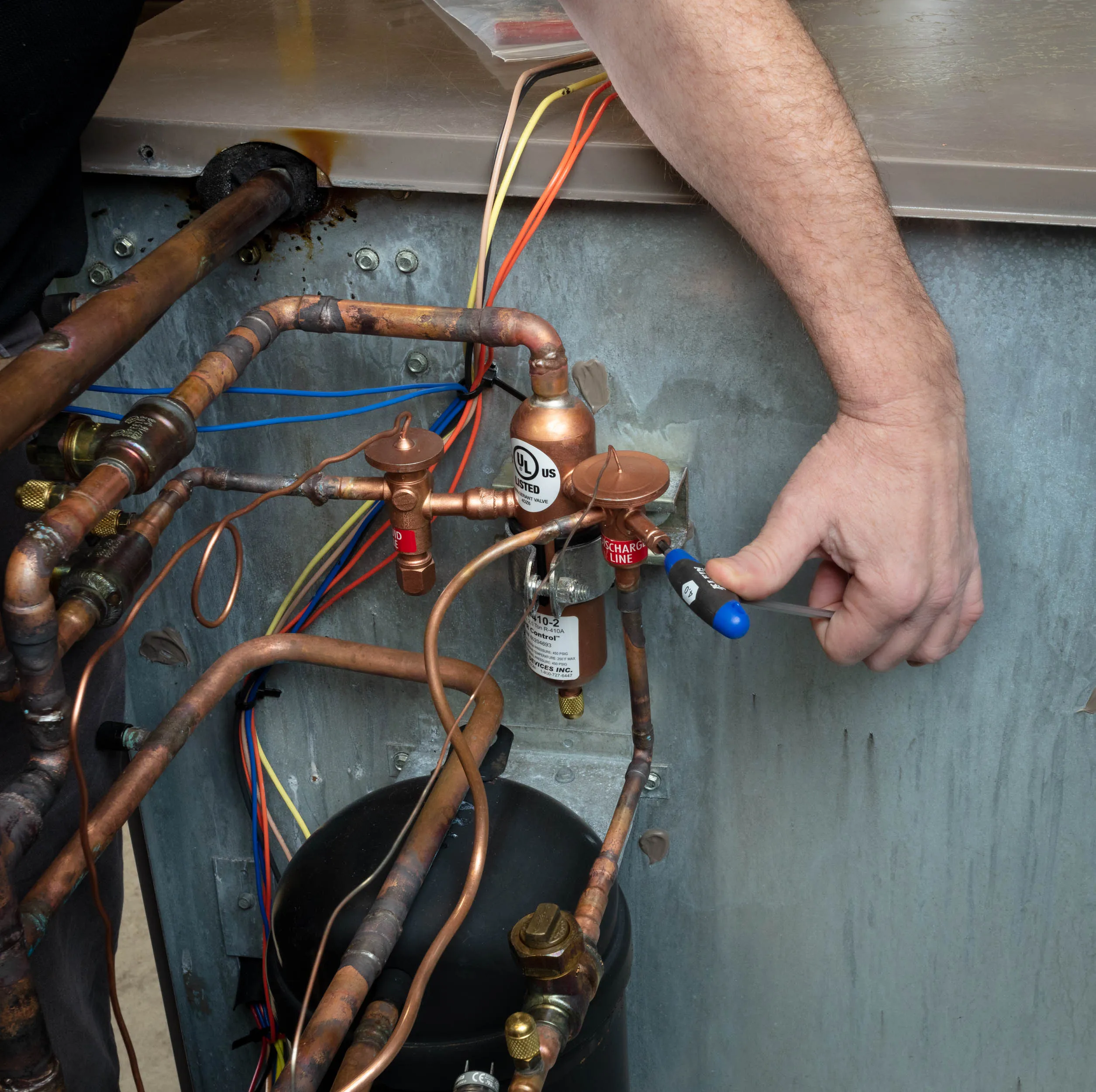

Siemens, Harvard’s exclusive service provider, identified the need for more precise environmental control without the complexity and cost of full system replacements. Paul Podesta, a Service Technician with Siemens, worked with the Rawal Devices technical team to retrofit the existing units with the APR Control, aligning with adaptive reuse concepts by repurposing the HVAC infrastructure to meet modern performance standards in a sustainable and cost-effective way.

The APR Control was installed to improve dehumidification to ensure consistent temperature and humidity stability — focusing control on the laser table environments themselves rather than attempting to manage the entire room. For over 15 years, this strategic retrofit not only improved performance but also helped extend the useful life of the existing HVAC equipment by reducing compressor cycling and system stress, ultimately supporting long-term reliability and operational longevity while avoiding the expense and complexity of variable speed systems.

Even as one unit remained R22 and the other was converted to 407C, the APR Control continued to perform reliably. Siemens and Rawal Devices collaborated closely to ensure the system was optimized during and after the refrigerant changeover.

The Result

Since the installation of the APR Control, Harvard’s laser labs have maintained critical temperature and humidity stability, ensuring uninterrupted operation and protection of sensitive experiments. This level of stability has been essential to minimizing environmental disruptions (re-alignment) and maximizing HVAC reliability.

After almost 15 years, The APR Control’s ability to protect the compressor while reducing stress on the system’s components has continuously contributed significantly to long-term HVAC system reliability and longevity. For Facility Managers, this translates to fewer complaints, less emergency maintenance, and increased confidence in existing infrastructure performance— all while maximizing the return on investment in current systems.

Conclusion

For universities and schools looking to enhance precision control in sensitive environments as part of adaptive reuse initiatives — without the budget burden of major equipment upgrades — the APR Control offers a proven, cost-effective retrofit solution. Harvard University’s success demonstrates that achieving long-term temperature and humidity stability — along with extended equipment life, reduced system wear, and enhanced operational longevity — is achievable with existing HVAC systems when paired with the APR Control.

Discover how the APR Control can improve environmental control, comfort, extend equipment life, and reduce costs for your facility by reaching out to our team to discuss your application here. Contact Us.