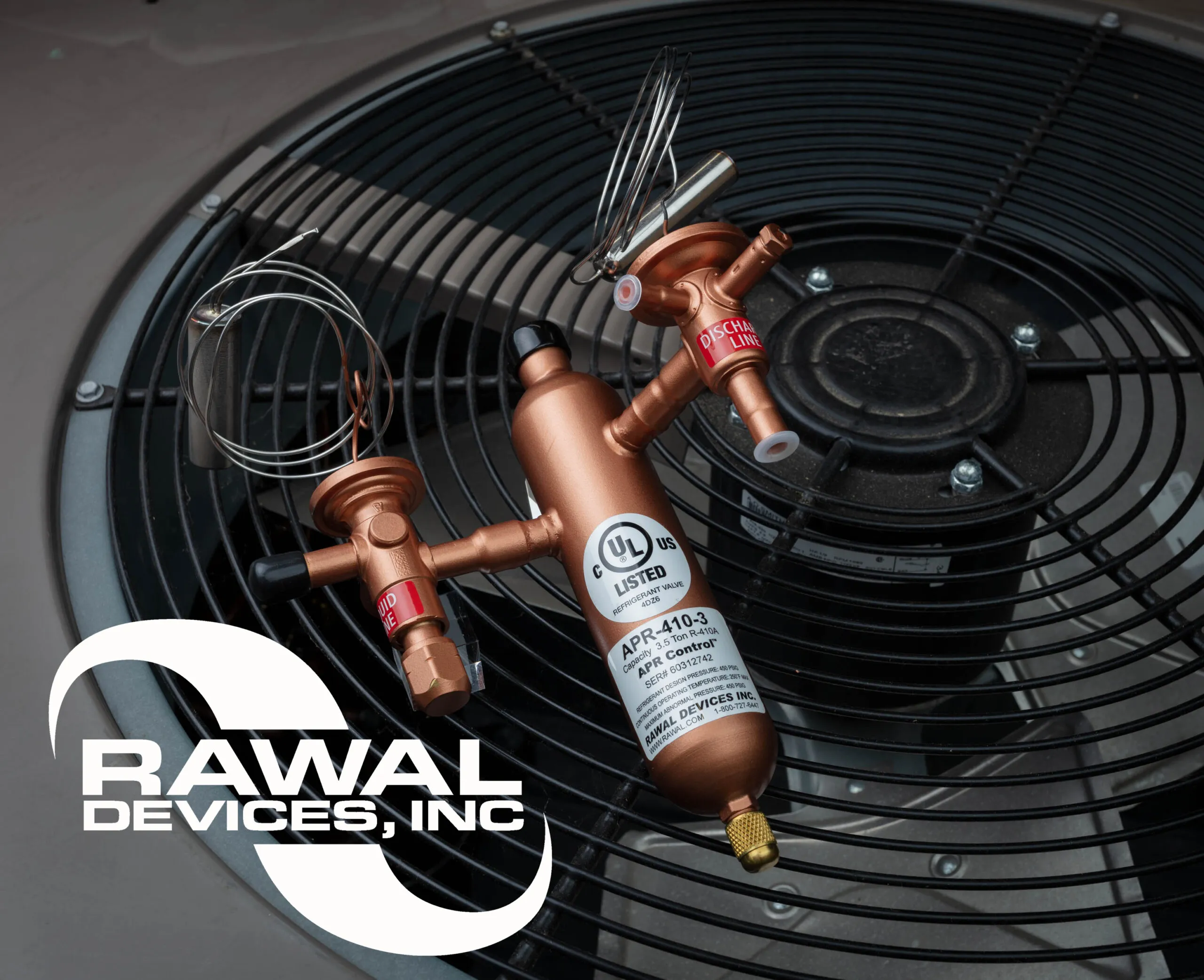

For restaurants looking to expand into existing spaces (renovations), start new construction, or simply improve the current HVAC system, the APR Control is the ideal solution. The Rawal Valve (APR Control) is a readily available and simple aftermarket solution that allows any restaurant to open their doors knowing their occupants and employees will be comfortable!

How Marco’s pizza ensured occupant comfort during expansion.

What has been one of the fastest-growing pizza chains, Marco’s Pizza, began expanding their locations by adding a few additional stores in the Houston, TX area. This expansion opened several renovation projects where they would be re-purposing old spaces for the new stores. Some of the spaces had existing in place equipment that would have been oversized for the space while others required new systems.

Being a restaurant, utilizing exhaust systems, Marco’s pizza knew they needed to address the anticipated humidity issues that would impact occupant comfort and food production!

Needing a capacity control solution, Marco’s Pizza brought in Teeter Engineering to serve as their MEP as they have in the past. It was decided that the APR Control served as the only option to achieve a system capable of the space demands, with lead times that could adhere to the project timeline. Long lead times from equipment manufacturers on newer equipment (at least 30 weeks), even longer if looking to add factory installed hot gas reheat (almost 54 weeks), would only stall their project deadlines.

Marco’s Pizza needed to stay on schedule in efforts to get the stores open and bring in customers, avoiding any costly delays!

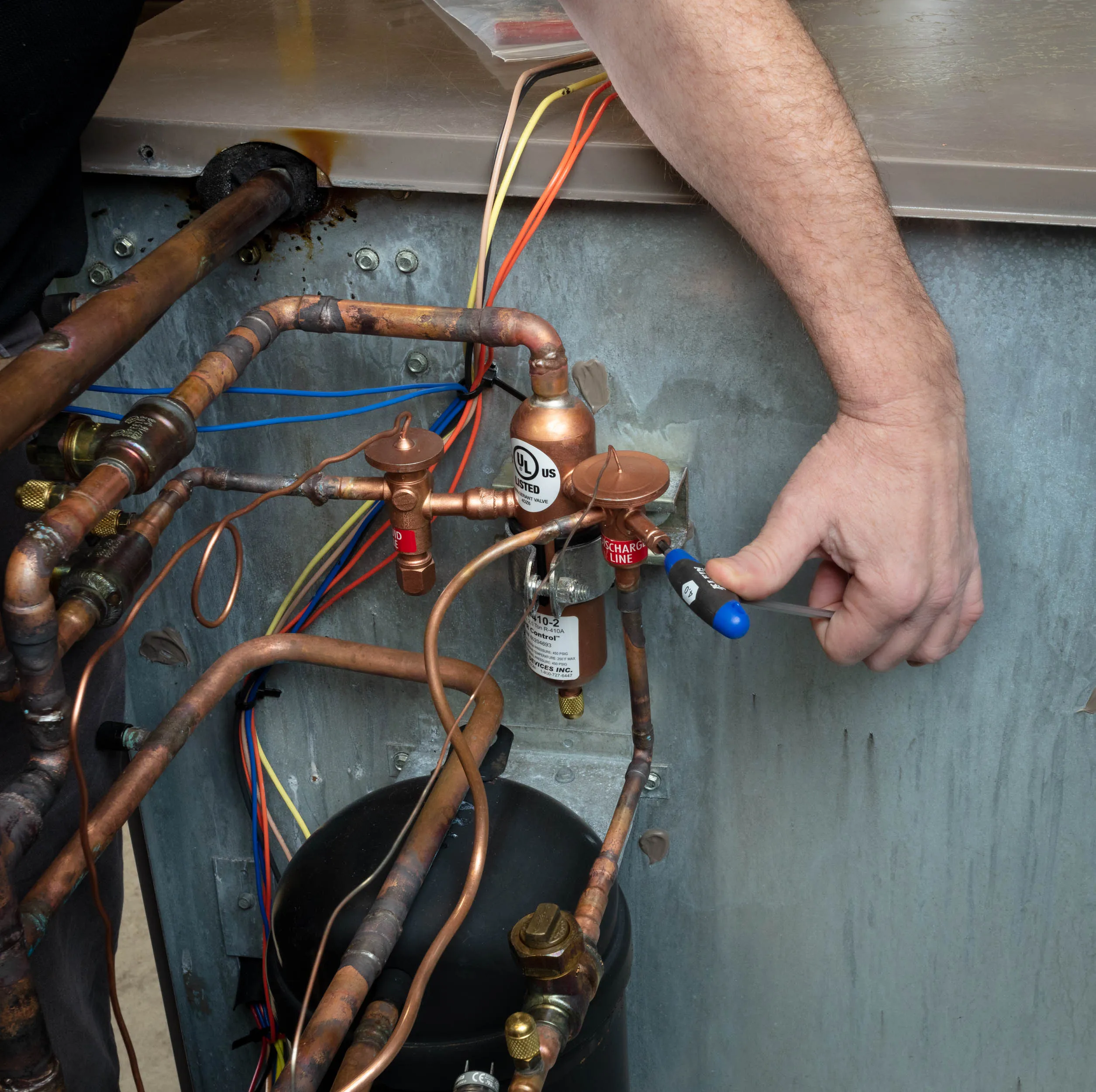

The Rawal APR Control was a readily available solution that could be used with the same effect as a factory installed Hot-Gas-Reheat option, which were only adding to the ever-increasing lead times to be installed on units. The APR Controls allowed the installing contractors to use in-place/existing equipment or order a standard off-the-shelf HVAC unit. All they needed to do was field install the APRs to ensure proper modulation & humidity mitigation, saving themselves from extensive lead times as well as some additional costs.

Marco’s Pizzas continued their expansion project, varying in new constructions and renovations of existing spaces, with this same Rawal Valve (APR Control) design approach on other franchises. Overall, the APR Control can provide a reliable and cost-effective solution to modulate system capacity while maintaining precise temperature and humidity levels in a wide variety of applications.

Rawal’s team of experts provide immediate and efficient over the phone application guidance, proper APR Control selection, and installation support. With the help of Rawal Devices Engineering and Technical support the application and installation are seamless. Give us a call to discuss your application today!