However, like all DX equipment, these Units are sized based on peak design conditions (which include variables such as occupancy, solar load, thermal gain and ventilation). Changing any of these variables, such as occupancy or renovating a space will cause the system to be oversized. Oversized air conditioning systems create a number of issues; the most important being poor indoor air quality.

Project Objectives:

Eliminate Cycling During Low Load Conditions with Reduced Fan Speeds

It’s hard enough keeping students focused; providing optimal temperatures in a classroom creates a more productive learning environment. Making sure the classrooms are comfortable is often a top priority for Educational Institutions. Unfortunately, this is difficult due to the fact that most air conditioning systems, including Unit Ventilators, only operate at design conditions approximately 5% of the year (according to ASHRAE). Unit Ventilators operating at less than design conditions creates below standard indoor air quality, this is exacerbated by the fact that airflow noise off the Unit Ventilator in the classroom disrupts the learning environment, which has driven the ASHRAE standard to require reduced fan speed. (ASHRAE depicts that the noise levels inside of a classroom cannot exceed NC 30. This is the equivalent of 40 dBA, or a conversation volume inside of a home).

The Nodaway Valley School District made renovations to their facilities which created complications with their existing R-22 (direct expansion) Unit Ventilators. These DX Unit Ventilators began to short cycle resulting in; poor indoor air quality, high humidity levels, and generally an uncomfortable learning environment. These problems all arose from the fact that the DX Air Conditioning systems were oversized for the spaces they were servicing.

In addition to poor indoor air quality, Nodaway Valley School District encountered noise from the Unit Ventilators, which exceeded the acceptable ASHRAE standard of NC 30. To address this problem, fan speed controls were installed to reduce airflow. Reducing fan speed eliminated teacher complaints about noise in the classroom because the air was no longer whistling through the grates, and it allowed the School District to be in compliance with the ASHRAE noise standards. However, the reduced fan speed resulted in a lower discharge temperature off the evaporator coil causing the (inactive) hot water heating coils to freeze and burst.

Engineered Solution:

Install the APR Control Valve for Capacity Control

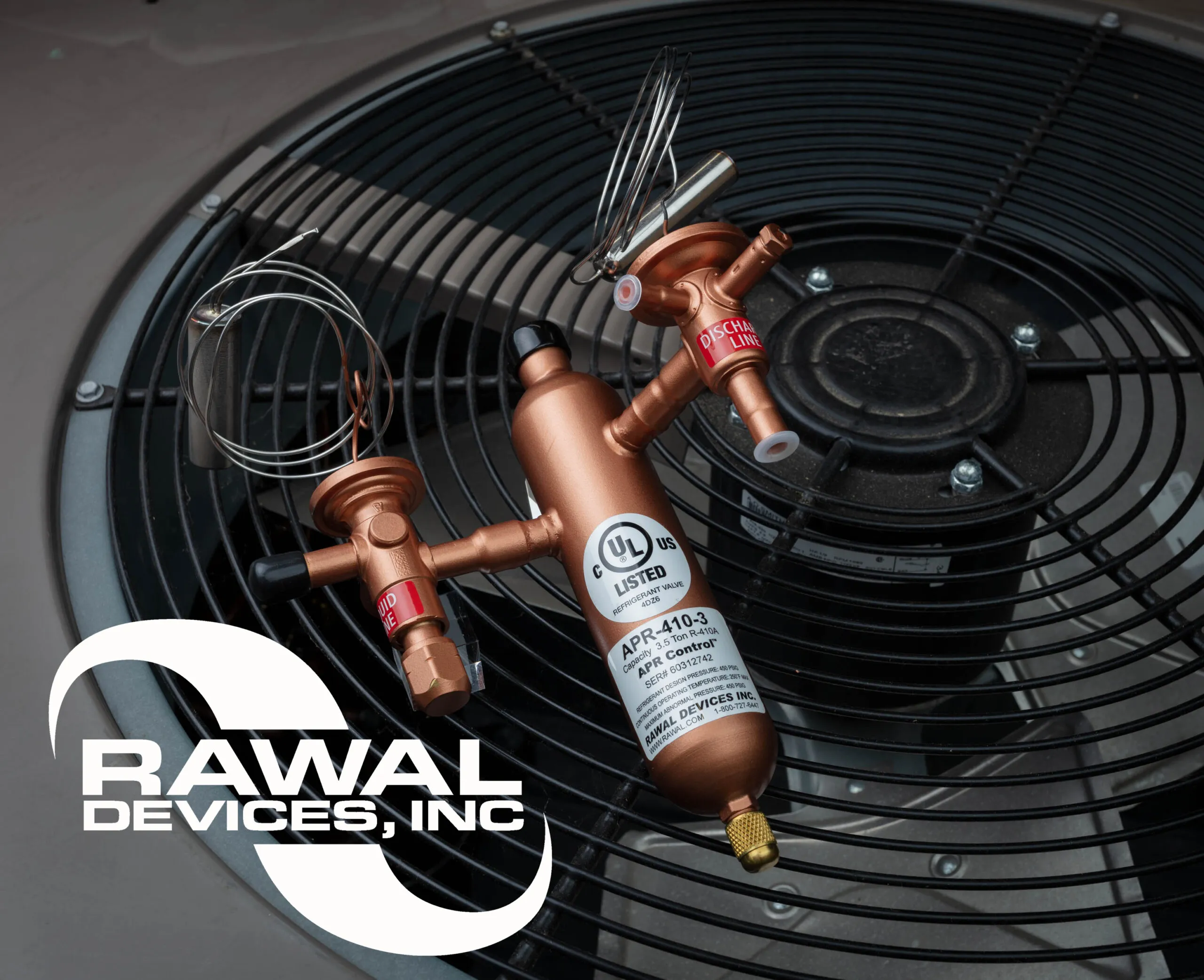

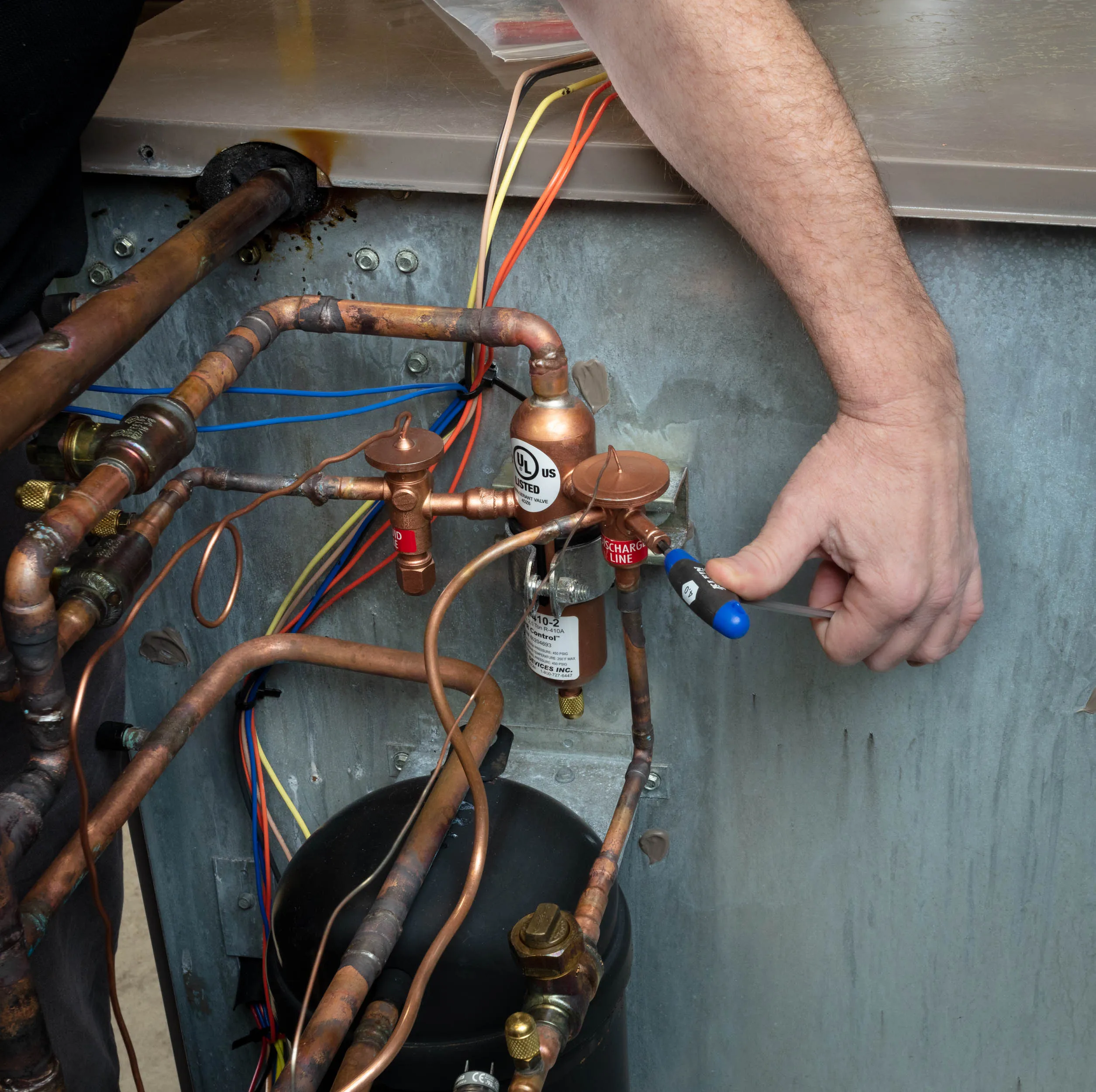

In order to address the situation, Nodaway Valley School District had two options; either replace the Units, or find a better way to control the capacity. Replacing the Units would have been a large financial undertaking that would have consumed a substantial portion of the districts renovation budget. The other option was to install the APR Control manufactured by Rawal Devices, Inc. which gives a system “continuous capacity modulation” and the ability to match the capacity of a system to the changing load conditions in a space.

Nodaway Valley School District chose to install the APR Control on all of their Unit Ventilators. This resulted in extending the runtime, while keeping the active portion of the coil below dew point for better dehumidification. The APR Control was able to stabilize the discharge air temperature preventing the inactive hot water coils from freezing and bursting. Furthermore, ASHRAE NC level standards require a reduced fan speed, which can result in evaporator coil frosting. The APR Control stabilizes saturated suction temperature, preventing coil frosting during low load conditions. Additionally, the APR Control helped prevent a broad spectrum of possible complications that can arise from using direct expansion Unit Ventilators such as; coil frosting, liquid slugging, and system failure.

Nodaway Valley School District is an example of one of the 1000’s of facilities to retrofit their oversized air conditioning system with the APR Control.

Since 1993, Rawal Devices, Inc. has been manufacturing the APR Control, a continuous capacity modulation and dehumidification device. The APR Control solves oversized air conditioning challenges; alleviating costly repairs, service call backs, customer complaints, and equipment downtime in new and retrofit applications.

Rawal Devices, Inc. can be reached at 800-727-6447 to assist with your oversized air conditioning challenges for New and Retrofit Air Conditioning Applications.