Background:

Mechanical HVAC systems can be the greatest limiting factor or the greatest opportunity to maximize productivity and profits in the indoor Cannabis Cultivation Industry. Those involved in cannabis HVAC system design, service, and operations are realizing that undersized or oversized systems from inaccurate load calculations for a given room lead to major challenges.

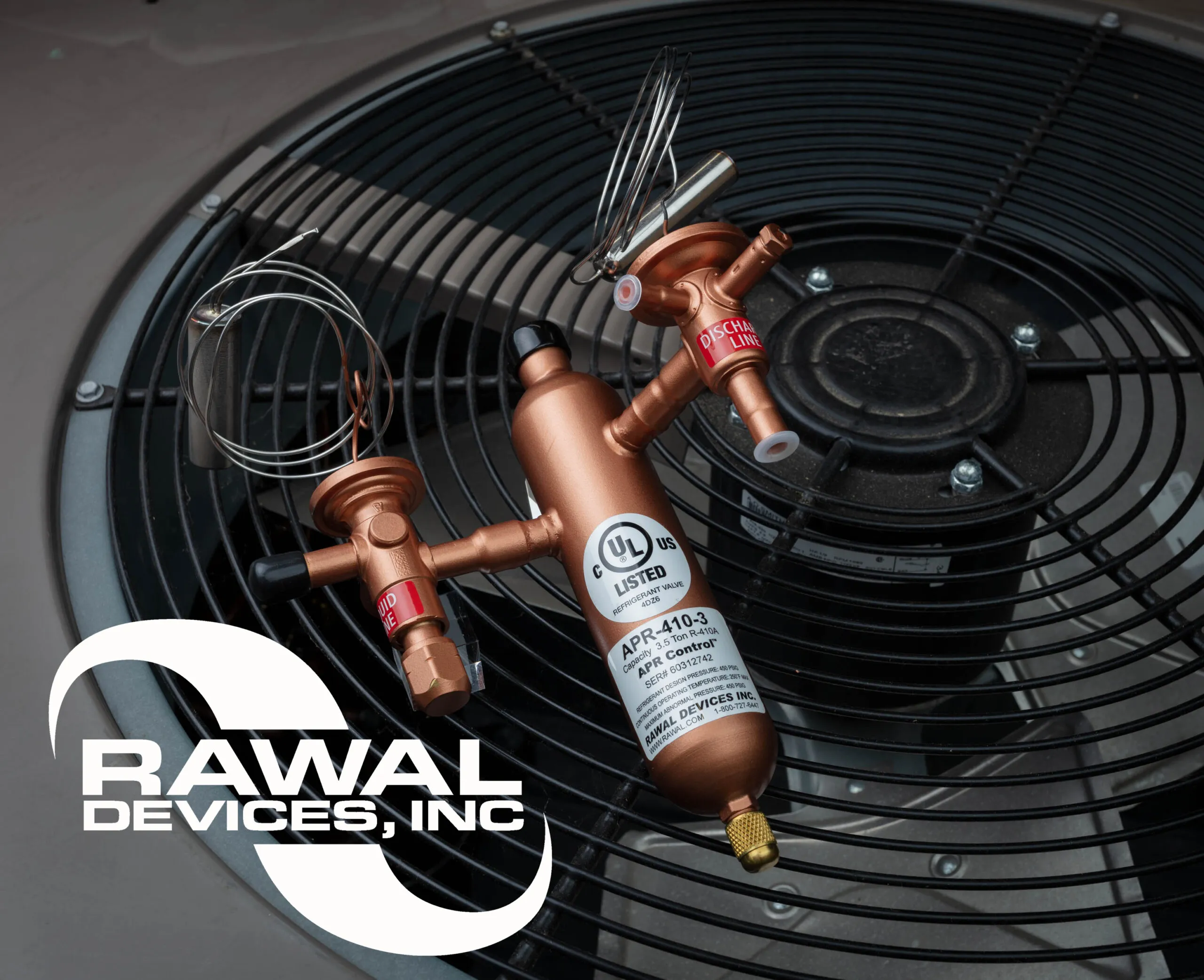

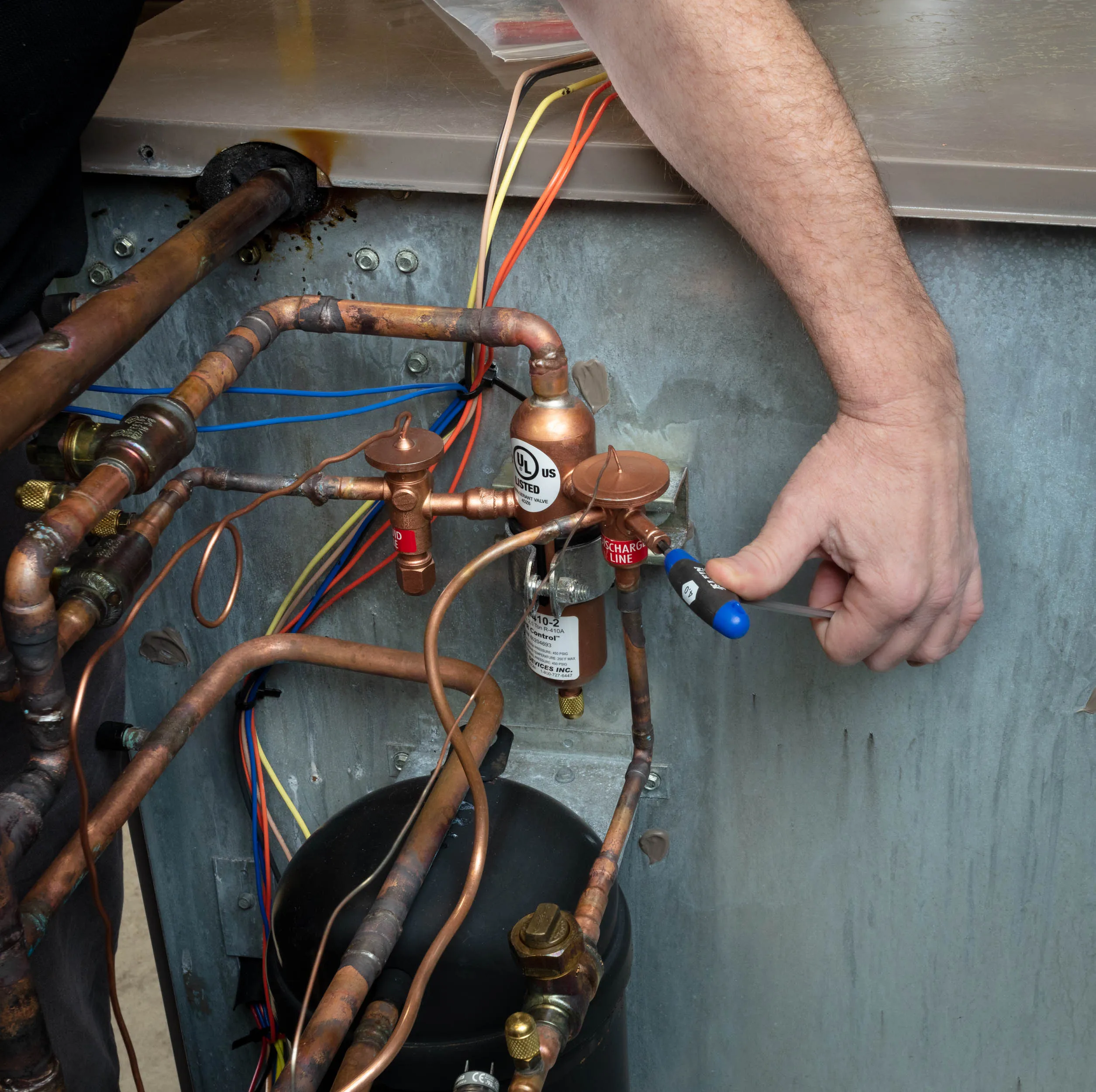

The lack of traditional funding for cultivators is a key contributor to underperforming HVAC design choices leading to poor crop yield and ultimately – Less Profit! Rawal Devices has seen poorly designed, and underperforming cultivation facilities that were in desperate need of control improvements without replacing the equipment. The APR Control will provide the perfect solution to improve both existing and new air conditioning equipment performance and reliability.

Rawal Devices has modulating technology, both mechanical and electronic, that transforms standard systems into variable capacity systems. This is critical for growing cannabis! With the APR’s ability to provide capacity modulation and precision discharge air control, your units will be able to meet ever-changing room criteria to maximize your plant yield and your customers’ profits!

Why should you be interested?

The cannabis industry has been experiencing a multi-million-dollar boom of about $11.5 billion in 2021 in the us, with an expected compound annual growth rate of as much as 20-30% annually projected through 2030. With the added benefit of increasing tax revenues exceeding $11.2 billion as of march 2022 for all legal cannabis sales (which started about 2014). According to research, in illinois, cannabis tax revenue has outpaced revenue from liquor taxes. More and more states are approving medicinal and recreational cannabis cultivation & consumption after recognizing the success of the medical product availability. Banking and challenges with finances can contribute to choosing inadequate and less expensive solutions. Increasing interest rates in the us may lead to more challenges in future funding for cultivation facilities and the required equipment.

Funding challenges force owners and operators of cannabis cultivation facilities to take a value engineered approach to cannabis grow room hvac and system design. Selection and installation of a sub-par system can ultimately affect the product output/quantity as well as quality. Budget or finance limited cannabis hvac designs can be fixed or improved with the application of the apr control. Rawal devices engineers are easily consulted for an initial understanding of how the apr will help! The apr control is not a “one size fits all solution.” our team will custom select an apr control based on your specific equipment and application needs.

The hvac system impacts all the parameters that are critical to plant growth. The plant’s health, growth rate, and crop yield all depend on meeting the optimal targets. Optimizing the room or environment must consider ranges for light, humidity, temperature, airflow, water, etc. To maximize the plant’s growth rate and yield, hvac systems must be able to support cannabis growing humidity range and meet the optimum conditions for all these parameters. The biggest challenge is that these optimal conditions change hour-by-hour, and sometimes even minute-by-minute.

Compared to other hvac applications (comfort cooling/offices and manufacturing spaces for example), few require as much control and dehumidification as cannabis cultivation and indoor plant environments.

The key to maximizing plant yield is recognizing the need for hvac equipment that can rapidly respond to the changes and maintain optimal conditions. Without having hvac included early in the facility planning process, the productive needs of a facility may fall far short of financial expectations. Not having affordable, available, and correct equipment choices puts cultivators at a major disadvantage. You are likely to need to call rawal devices to help you correct some of the sacrifices the facility was forced to make.

Transpiration & vpd (vapor pressure deficit)

Transpiration (release of water vapor by the plant into the air) is the primary source of humidity being generated in the sealed grow room that needs to be dehumidified by the hvac system. As plants grow and get bigger their water demand increases and they transpire greater volumes of water into the space, contributing to the high latent load.

The rate of transpiration can be directly affected by temperature and relative humidity levels in the room, referred to as vapor pressure deficit (vpd). If an indoor cultivation space’s vpd is too low, you run the risk of a slower growth rate, mold, or root-rotting. If your vpd is too high, that will reduce or limit the rate of transpiration, resulting in over-drying the plant (also known as “tip burn” or “leaf curl”). Both potentially resulting in damaged saleable crop!

Understanding the optimal range for vpd at different temperature and humidity levels, is essential to the success of the indoor cannabis cultivation operation. Any non-modulating standard piece of equipment will never allow you to maintain the optimal vpd conditions 24/7. The apr control responds to the load profile in the space, in real-time, providing capacity modulation to maintain the ideal environment conditions to achieve optimal vpd and rates of transpiration – maximizing growth rates for increased profits!

Lighting & scheduling

Light intensity also affects the moisture in the space as it can increase the water demand and transpiration rates. The lights turning off and on throughout the day are by far the most challenging transition periods that a mechanical system must respond to.

The plants release most of their moisture into the air when the lights are on. In a flower room about 75% of the moisture needs to be removed during the “lights on” period. As the lights turn off, there is an immediate shift in the sensible to latent heat ratio as the temperature drops and the relative humidity spikes. This requires a significant amount of dehumidification and can be overcome again with an apr control enhanced system.

Having to accommodate for such a dramatic shift in load changes may lead to oversized hvac systems that only present more challenges. Integrating the apr control into your hvac system results in stable temperature and humidity control for the grow room environmental management system.

Conclusion:

The apr control is the perfect temperature and humidity control solution for cannabis grow room hvac challenges!

For traditional hvac applications, like offices or even labs, there are published standards from industry organizations that engineers can refer to for guidance when sizing and selecting equipment. Since the legalization of the cannabis industry is so new, there are few good standards for indoor plant environments for engineers to refer to.

The apr control can benefit system operation on such dynamic spaces, providing exceptional control and ultimately improved product and yield. The apr control is the perfect low-cost solution for challenging cannabis hvac systems!

Being able to load match perfectly and proportionally in response to ever-changing optimal cannabis grow room conditions, the apr control will improve new and existing equipment to produce maximum plant yield and increased profit margins!

To all engineers, contractors, facility owners, or cultivators facing indoor cannabis grow room hvac challenges, please contact the rawal devices team!

Our goal is to ensure your success as we are happy to discuss the many issues that the apr control can help solve or prevent when dealing with dx air conditioning for your specific applications.