All this machinery requires quick responding HVAC equipment to be able to meet the rapidly changing load demands of the room and avoid short cycling to protect the scanning equipment.

When it comes to repurposing any space (design/build HVAC or retrofit applications), determining if existing equipment can meet the new load requirements and can be reused are important factors in cutting the job costs. Installing new HVAC equipment and adding any additional ductwork is expensive!

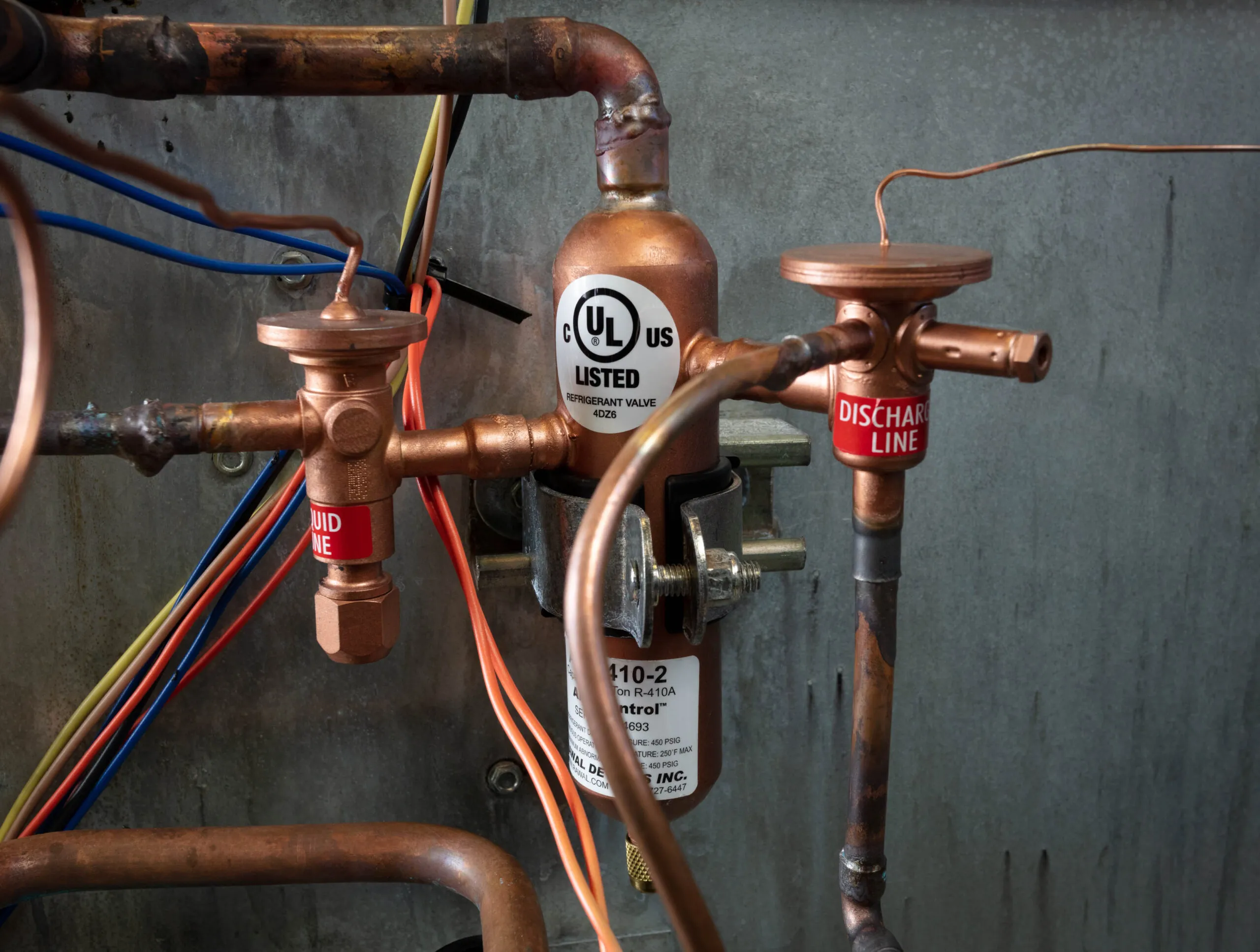

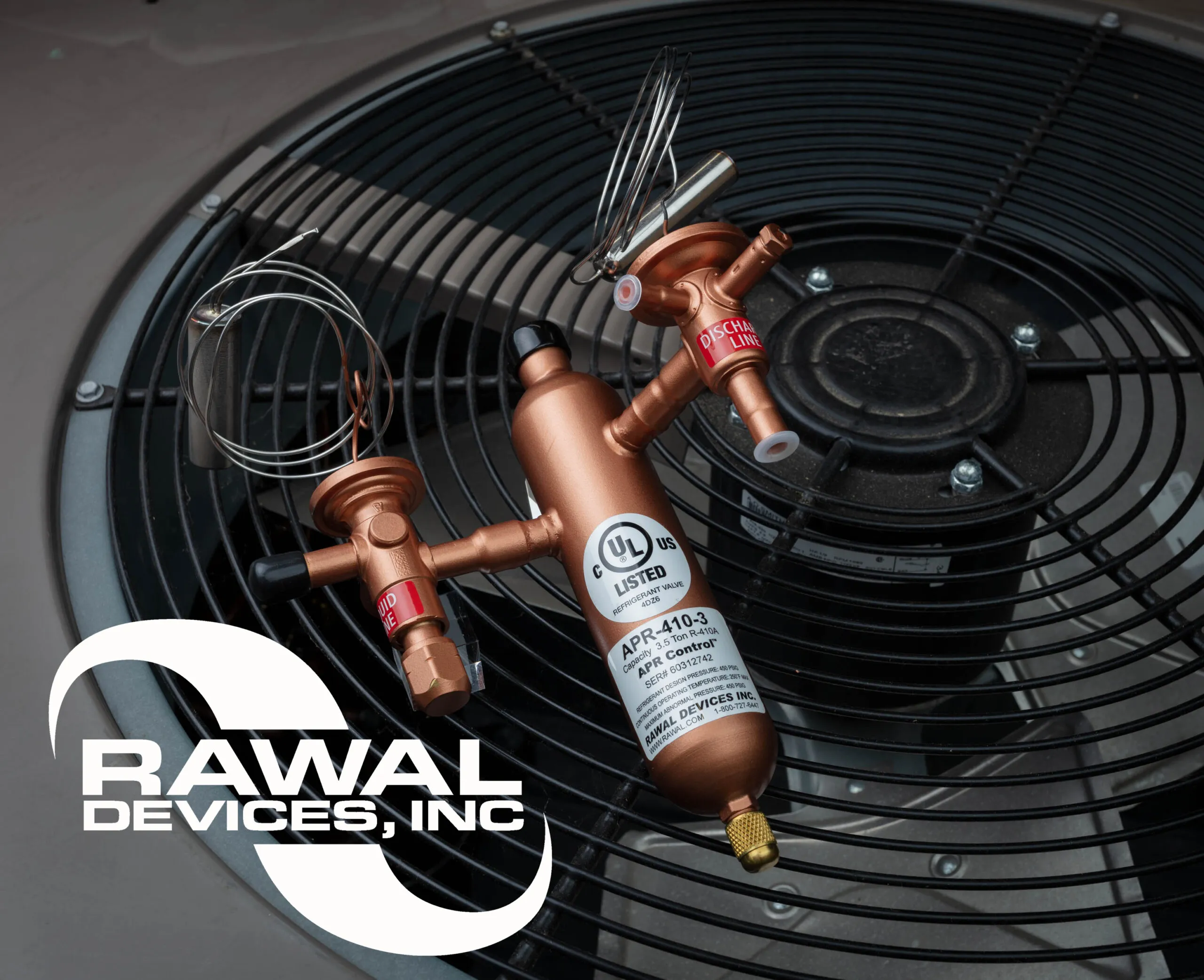

The APR Control by Rawal Devices was the perfect value engineering solution for All Florida Mechanical. Tower Radiology hired them to modify the existing (repurposed) spaces but prioritized keeping costs down by reusing the existing DX equipment. Using the APR Control for continuous capacity modulation allowed them to meet the strict space parameters while enabling the equipment to respond to rapidly fluctuating demands. All while keeping the overall project costs down significantly, here’s how!

Project objectives

Retrofit existing hvac systems to meet new space requirements

Tower Radiology offers a broad array of imaging services from screening mammograms to advanced MRI’s. Maintaining precise temperature and humidity levels at these radiology outpatient centers is critical as sensitive medical equipment is used and strict environmental control is required. To maximize performance and avoid overheating damage, All Florida Mechanical needed to maintain proper temperature and humidity levels in the room.

Inside these imaging rooms, when the radiology machines are in operation, the space usually requires the full cooling capacity from the HVAC equipment. However, as soon as the scanning machines turn off, the load in the space drops to almost nothing. Most standard HVAC equipment is not able to maintain temperature & humidity levels in these spaces. Tight parameters cause frequent and rapid shifts in capacity demand.

Having a rapidly responding HVAC system with an APR Control will prevent repeat service calls from performance and reliability issues, and eliminate the dreaded short cycling alarms!

The goal of this project was to reuse the existing HVAC equipment if it could meet the load demands of the space. It was determined that the equipment could adequately maintain temperature according to new load calculations. And, there was no desire to purchase and employ costly new equipment, so adding the APR Control to the existing HVAC equipment was an acceptable solution.

Contractor/ service technician solution

Install the apr control to prevent extreme temperature and humidity swings

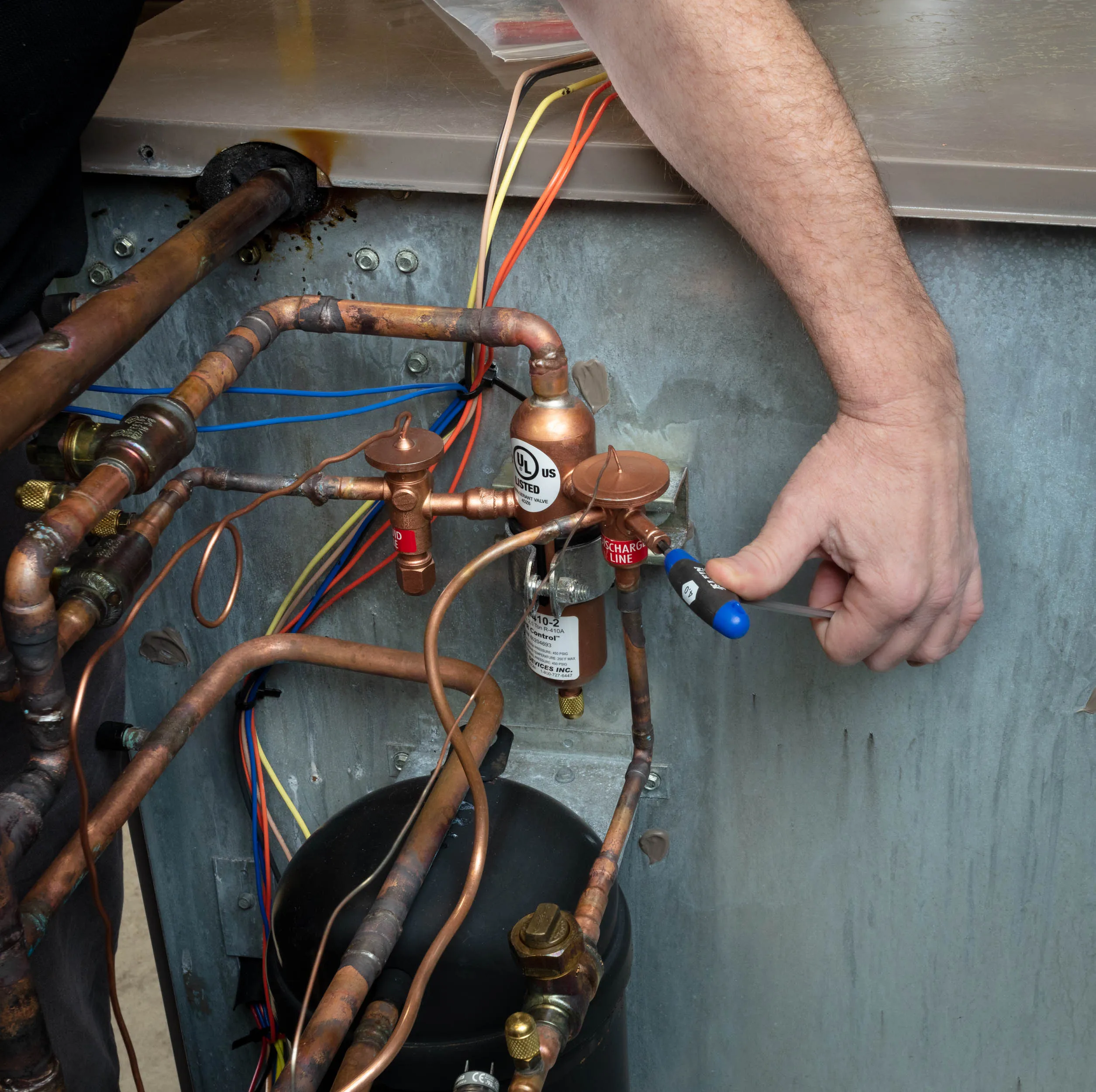

It was up to Jim Hartman, VP of All Florida Mechanical, to avoid costly equipment replacement and find a cost-effective solution to re-use the existing equipment. The APR Control will modulate new or existing HVAC systems’ capacity to match the rapidly changing load requirements of the space and make it the most cost-effective solution. Radiology outpatient centers are subject to regulations from organizations such as the FDA. Maintaining proper environmental conditions is a critical aspect of compliance. The APR Control can help ensure that the facility operates within acceptable limits and avoid the regulatory issues.

The standard DX equipment usually can meet the demands of the new medical and scanning equipment because the new machines require less cooling with advancements in medical machine technology. Installing the APR Control in the HVAC equipment allows the HVAC equipment to modulate capacity quickly, extending the runtime of each unit to maintain precise temperature and humidity levels at Tower Radiology outpatient centers.

Jim Hartman stated, “At All Florida Mechanical, we use the APR Control valves on all equipment for MRI rooms, since those units run all year long and are critical to keeping the humidity down around 48%-52% percent with temperatures around 68°F- 72°F.” Jim continued, “I have found that buying a mid-range, maintenance friendly unit and adding APR valves to it does the trick.”

“I have been installing the Rawal APR valves for over 20 years plus and never had an issue,” said Jim. All Florida Mechanical Services, Inc. is a certified HVAC Mechanical contractor that services, sells and installs HVAC equipment, covering a broad range of applications from medical to hospitality. They also provide high-quality service and maintenance of any and all air conditioning systems – specializing in 100% outside air systems.

Overall, the APR Control can provide a reliable and cost-effective solution to modulate system capacity while maintaining precise temperature and humidity levels in a wide variety of applications, including radiology outpatient center, ensuring the safety and comfort of patients and staff.